LEAD serves the global cement industry with the Detailed & Review Engineering Services (Concept to Commissioning) collaborating with all the disciplines such as Process, Mechanical, Civil & Structural engineering.

At the civil and structural engineering stage it includes Analysis & Design of RCC and Steel Structures for all cement plant structures.

- Analysis & Design of RCC and Steel Structures for all Plant & Non Plant Buildings

- Crusher Building,

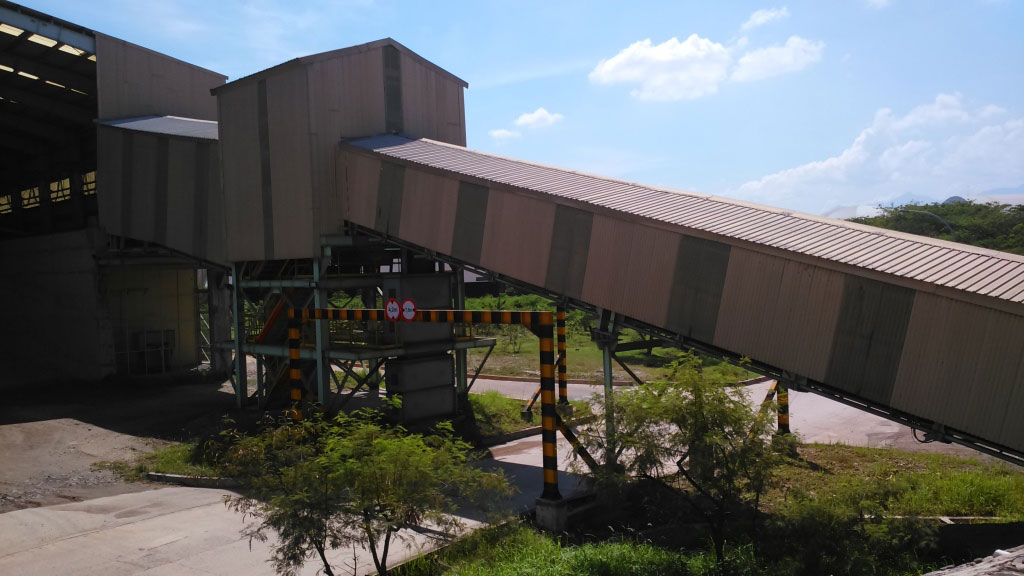

- Conveyors Galleries & Trestles

- Stacker & Re-claimer Sheds, Foundations etc

- Raw Material Hoppers, Raw Mill Building, Pre-Heater Building, Kiln Piers, Cooler Building, DPC & Clinker tank,

- Coal Mill Building & Hoppers

- Cement Mill Building, Mill Foundations, RCC hoppers, Silos,

- Packing Plant Building, Wagon Loading and Bulk Loading termials etc.

- Raw Mill Buildings, Raw material Hoppers, Conveyors, Large Industries like power plants, cement plants, steel plants etc.

- RCC Chimneys

- Steel Stacks

- RCC & Steel Bunkers

- Vibration Analysis of Dynamically Loaded Equipment Foundation & Structures

such as Cooler Fans, Mills, TG Foundations etc. - Material handling structures like Transfer towers, Conveyors, DPC etc

- Retaining Structures

- Pile Foundations, Well Foundations, Sheet Piling & Coffer Dams

- Joint Detailing of Steel Structures both Welded and Bolted

- Settlement Analysis of Structure & Foundation

- Underground RCC Tunnels

- Architectural Design and Detailing

- Design of Intake Structures

- Structural Optimization Study & Recommendation

- Retrofitting and Strengthening of Existing Structures

We also support the cement industry with structural optimization, retrofitting and strengthening of existing structures.

Our architectural support to the cement industry includes conceptual design, preliminary design, and preparation of tender drawings, detailed design for non plant buildings such as Administrative buildings CCR Buildings, Boundary Walls etc.

The mechanical engineering support for the cement industry includes

- Developing lay outs

- Developing General Arrangements of different departments

- Developing Material Handling Systems

- Developing Flow Sheets

- Detailed design and fabrication drawings for different types of pressure vessels, pressure and utilities like piping, Bulk storage silos/tanks using national and other codes like Euro, ASME etc.,

- Selection of materials for construction

Developing and Detailing of Utilities like,

- Venting system (De-dusting systems)

- Piping for compressed air and circulating / process water system

- Fabrication details of material conveying chutes with BOM.

- Details of supporting systems for above.

- Engineering for Retro-fitting and system improvement.

- Preparation of Technical Specifications of various Bought outs and main machinery for cement plants as per system requirement like, Material conveying equipment (Belt conveyors, Bucket Elevators, Screw conveyors etc.) Control equipment like various gates, (slide gates, rod gates dampers, Rotary valves etc.). Connecting equipment like Expansion Joints, Bellows etc. Piping, Dust collection Equipment, and Fans (Process as well as Auxiliary systems)

- Developing compressed Air and Circulating water/ Process water distribution based on system requirement and also developing required piping layouts including piping sizing.

- Fabrication details of steel stacks with BOM for both guided and self supported type.

- Vetting of all suppliers Engg. /Spec. / Drgs.

- Auto CAD is used in developing drawings and drafting standards are maintained at international level

equipment using national and other codes like Euro, ASME etc. We also offer support on selection of materials for construction.

At the start of the cement projects we coordinate with the main civil sub contractor, help in supervision and structural work and ensure quality control.

- Ambuja Cements (for FL Smidth) Kodinar, Gujarat

Lime Stone Crushing and Screening System

Wobbler Crusher Building

Surge hoppers

Conveyors

Dump hoppers

- Zuari Cements (for FL Smidth) Yerraguntla, AndhraPredesh

MRSS Building

Substation Buildings

- Vikat Sagar Cement Pvt.Ltd. (for FL Smidth) Chatrasala, Karnataka

Cement Mill Hoppers Building

Cement Mill Load Center Building

Cement Mill Building

Mill Foundations

Conveyors and Transfer Towers

Substations Buildings

- Heidelberg Cements (I) Ltd.,(for FL Smidth)

- 5000 TPD New Clinkerisation Plant, Narsingarh, Damoh, M.P. India)

321 Design of Raw mill Building & Associated Structures

461 Design of Coal Mill Building

Machine foundations for Raw mill, Coal Mill, Booster fan and Coal mill Fan.

Mill Foundations

Shed for Booster fan & coal mill fan

Steel staircases upto +47.80 m height

EOT crane girders

Steel platforms & miscellaneous structures

Design of Raw Material Hoppers, Conveyors & Transfer Towers

Design of OLBC Conveyers

Design of OLBC Substations (SS1 to SS4) Four Numbers

Design of Duct Supports

Material Handling Load Center ER-1

491 Substation (Cooler)

493 Substation (Coal Mill)

311 Raw Mill feed Conveyors

- Expansion of Cement Grinding Unit at Imlai, Damoh, M.P

Clinker Transport MCC Room

891 MRSS Building

591 ER-5 Building

- Expansion of Cement Grinding Unit at Jhansi, U.P. India

Clinker Transport MCC Room

MRSS Building

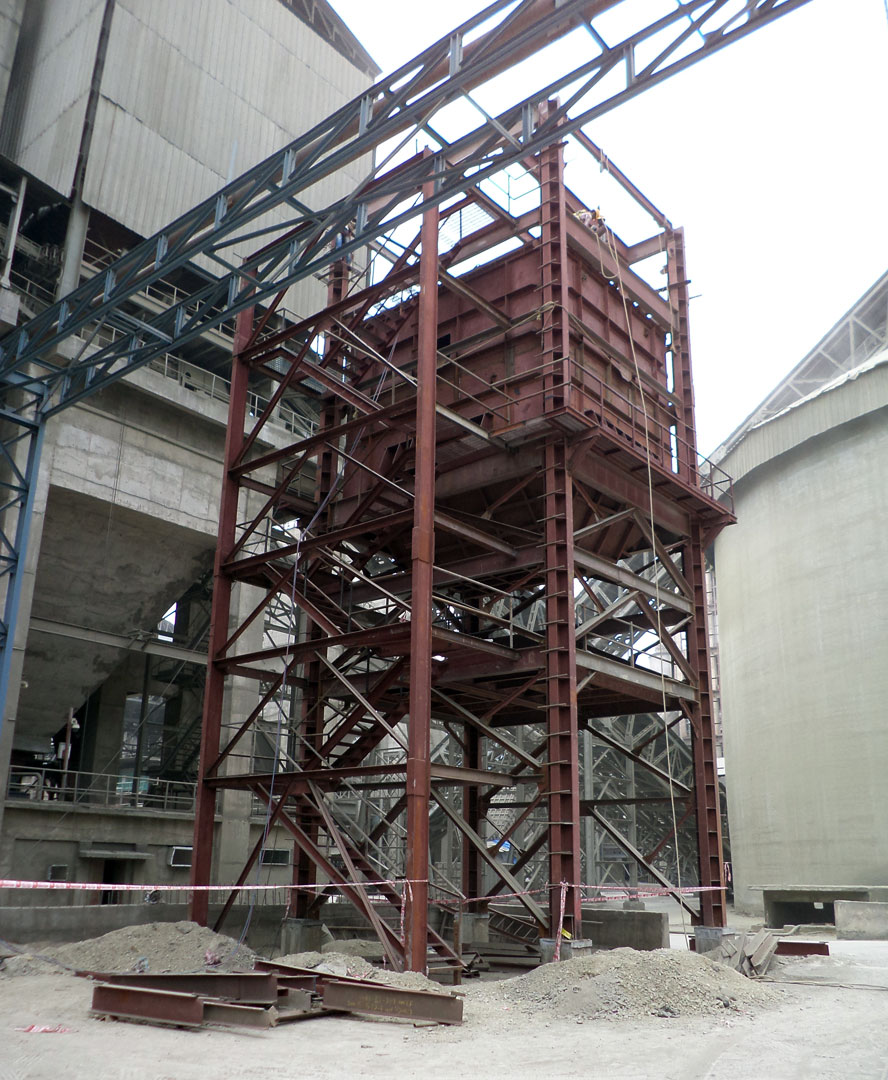

471 Transfer Towers (TT1)

471 Belt Conveyor BC 060 & 250

511 Conveyors & Transfer Towers

- ACC (Wadi)

Miscellaneous Steel structures and structural audit of existing structures

K3 ESP modifications

Design of Duct Supports

Design of Fan Foundations

Design of bag filter supporting structures

DPC 1 & DPC4 installation after modification of clinker handling system

Installation of magnetic separator system for coal handling circuit

Integration of belt conveyor system for limestone crushers 2&3

Design of special platform for main chimney monitoring system (New Wadi unit)

- DPC – 1A

Strengthening of existing DPC – 1A trestle

- Power Plant fly ash silo

Strengthening of existing fly ash steel structure

- Power Plant fly ash silo

Strengthening of existing fly ash steel structure

- Clinker Tank

Strengthening of clinker tank roof

- By pass arrangement for fly ash in cement mill building

Design of steel bin

Design of Bag filter venting & duct roofing

Design of supporting structure for steel Bin

Design of trestle for air Slide

- Grate cooler

By pass arrangement at grate cooler to existing coal mill hot air duct

Design of steel structure at grate cooler

- Coal Handling System

Design of steel Structure for connection L3/BC5 & L3/BC6

Design of Transfer Tower

- Coal Handling System

Design of duct for VRM

Design of steel structure for new duct

- ACC Sindri – Jarkhand

Coal Mill Building

Coal Dosing & Firing System

- Cementos Argos – SA Antiqota, Columbia

Recirculation Building

Bucket Elevator Tower

- Oman Cement Company, Rusayl

Cement Mill Substation

- ACC (Thondebhavi)

Design of bag filter Supporting structure

Design of duct supports from wagon tippler bag filter

Design of wagon tippler structure

Design of Gypsum Storage System Modification

- Proposal for Winch arrangement for pre-heater building

- Design of steel structure for 5T Power winch

- Clinker Handling

- Design of steel Bin

- Design of venting arrangement for steel bin

- Design of steel structure

- Vasavadatta Cement (Sedam)

Structural audit of steel structures of all 4 units (for FL Smidth)

Clinker Bulk loading system for UNIT IV

Integration of cement Mill 2 and unit 1 clinker stock pile

Redesign of DPC 1and strengthening of penta house and central shaft for integration with cement Mill 2 hoppers

Design of cable galleries

Monorail arrangements for critical handling of mill drives

Design of new higher capacity feed hopper for polycom

Clay separation system

- Development of layout for Proposed 1.5MTPA Grinding Unit at HOTGI

- Packing Plant at Sholapur

Packing Plant Building

Bulk loading system

Cement silo supporting structure

Empty bag godown

Administration and all miscellaneous. Buildings and other services including roads & drainage

- Proposal for Bag filter arrangement for polycom

Strengthening of existing steel structure in entire Building

Designing of duct roofing for polycom

- Proposal for Bag filter arrangement for fly ash bin

Designing steel structure for Bag filter

Design of Bag filter venting

Design of Duct roofing for Bag Filter

Design of Bag filter venting for fly ash ….. System.

- Deccan Cements, Hyderabad

Design of wagon loading system (civil & Structural)

- Parasakti Cements, Hyderabad

Gypsum shed and miscellaneous Structures

Precalciner Duct Supporting

Structure (Zambezi Cement)

Blending silo condition monitoring and design of rectification

Bucket elevator supporting Structure

- India Cements, Vishnupuram

Community Hall and Auditorium for 1000 capacity and officer club

- Mahi Cements (India Cements Ltd.)(for FL Smidth)

Design of Packing plant & Bulk Loading System

- Proposal for Winch arrangement for pre-heater building

Design of steel structure for 5T Power winch

Clinker Handling

Design of steel Bin

Design of venting arrangement for steel bin

Design of steel structure

- Proposal for Bag filter arrangement for fly ash bin

Designing steel structure for Bag filter

Design of Bag filter venting

Design of Duct roofing for Bag Filter

Design of Bag filter venting for fly ash ….. System

- K. Lakshmi Cement Ltd. (for FL Smidth)

Work shop & Store Shed

Coal Mill Building and associated structures

Coal Mill Substation

- Suvarna Karnataka Cements Pvt. Ltd, (for Vasavadatta Cement)

500 TPD clinker grinding unit

Design of Mill foundation

Raw Material of Hoppers

Modification fo cement silos and Packing plant

Design of Extension of Gantry Girder

Design of foundation for Dryer

Material handling System

- Indo Cement Jakartha (Citeureup PCC Improvement & Capacity Expansion Project Citeureup, West Java)

- Trass Crushing Storage & Handling System

Detailed Engineering Services for the entire Trass Crushing and Handling System and Preparation of Tender Document

- Trass Crushing Plant

- Metal Separator House

- BC-RH.01

- Transfer Tower TT-1

- BC-RH.02(Stacker & Reclaimer)

- Trass Storage Hall

- Modification of Exist. Limestone Circular Storage

- BC-RH.03

- BC-RH.03.04A

- Transfer Tower TT-2

- BC-RH.03.04B

- Transfer Tower TT-3

- BC-03.04C & BC-RH.03

- Infrastructure (Trass Dumping Area, Roads, Culverts & Drainage, .)

- Clinker – Trass & Handling System

- Clinker from P7, P8, and P11

- P11 Clinker Silo Discharge Modification

- Transfer Tower TT-1

- Clinker Belt Conveyor BC-CL01

- Transfer Tower TT-2

- P7&P8 Clinker Silo Discharge Modification

- Transfer Tower TT-3

- Transfer Tower TT-4

- Clinker Belt Conveyor BC-CL02

- Transfer Tower TT-5 (Bucket Elevator Tower)

- Supporting Structure for DC-14

- Clinker Belt Conveyor BC-CL03

- Chain Bucket Elevator BE-CL01

- Chain Bucket Elevator BE-CL02

- Supporting Structure for Two Way Diverter TW-CL01

- Clinker Belt Conveyor BC-CL06

- Supporting Structure for All Transfer Chutes

- Foundation & Supporting Structure for Compressed Air Piping (if any)

- Clinker from P6

- Clinker Belt Conveyor BC-CL07

- Supporting Structure for Dust Collector DC-07 at Mill Feed (Dosing Building)

- Supporting Structure for All Transfer Chutes

- Foundation & Supporting Structure for Compressed Air Piping (if any)

iii. Unloading Station for Clinker from P1, P2, P3, &P4

- RC Pit for Clinker Hopper

- P1, 2, 3 &4 Clinker Unloading Station (incl. support for Belt Feeder)

- Clinker Belt Conveyor BC-CL04

- Transfer Tower TT-6

- Clinker Belt Conveyor BC-CL05

- Transfer Tower TT-7

- Supporting Structure for All Transfer Chutes

- Foundation & Supporting Structure for Compressed Air Piping (if any)

- Additives Handling System

- Belt Conveyor System inside the Dosing Building

- Reversible Belt Conveyor for Transs RBC-TR01

- Additive (Limestone) Belt Conveyor BC-LS01

- Reversible Belt Conveyor for Limestone RBC-LS01

- Supporting Structure for Two Way Diverter TW-LS01

- Supporting Structure for Dust Collector DC-08

- Supporting Structure for All Transfer Chutes

- Supporting Structure for Compressed Air Piping (if any)

- Transport Belt Conveyor to P6

- Additive (Limestone) Belt Conveyor BC-LS02

- Supporting Structure for Two Way Diverter TW-LS02

iii. Transport Belt Conveyor to P11

- Additive (Limestone) Belt Conveyor BC-LS03

- Additive (Limestone) Belt Conveyor BC-LS04

- Reversible Belt Conveyor (Limestone) RBC-LS02

- Additive (Limestone) Belt Conveyor BC-LS05

- Reversible Belt Conveyor (Limestone) RBC-LS03

- Additive (Transs) Belt Conveyor BC-TR01

- Additive (Transs) Belt Conveyor BC-TR02

- Reversible Belt Conveyor (Trass) RBC-TR02

- Additive (Transs) Belt Conveyor BC-TR03

- Transfer Tower TT-8

- Transfer Tower TT-9

- Supporting Structure for All Transfer Chutes

- Foundation & Supporting Structure for Compressed Air Piping (if any)

- Belt Conveyor Gypsum from Belt Conveyor LB-14 (Existing)

- Additive (Gypsum) Belt Conveyor BC-GY01

- Additive (Gypsum) Belt Conveyor BC-GY02

- Supporting Structure for Two Way Diverter TW-GY01

- Supporting Structure for All Transfer Chutes

- Prism Cement, Satna, Madhyapredesh

Review of design of steel structures inside Blending Silo, steel dome of

Clinker Tank & connected DPC Gallery along with review of designers rectification recommendations

Failure analysis and it’s report of structure inside Blending Silo

- Hamriyah Cement Company for CEMTEC (Austria) & UNGER Steels, UAE

Design of Conveyors

Design of Transfer Tower

Design of Silos

- CEMTEC (Austria) & UNGER Steels, UAE

Pre bid Engineering services for the proposed stock piles for Clincher & Gypsum

(Circular stock piles & 75mm dia and 54mm dia each)